If I have to use one word to describe today’s travel in Marumori(丸森町), I will choose “unduplicated”. There are so many “first-time-in-my-life” experiences in Marumori. Please forgive me for knowing so little about the world and being shallow, but I was really touched by the experiences in Marumori.

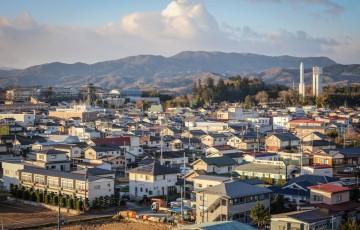

Marumori is located in the most southern portion of Miyagi Prefecture, it takes one-hour drive from Sendai to Marumori. The name of the town comes from its location of a circular basin surrounded by heavily forested mountains; “Marumori” means “circle forest” in Japanese. The Abukuma River passes through the town.

丸森手すき和纸工房-A Precious Japanese Treasure

The Marumori Washi Workshop (丸森手すき和纸工房) was owned by the Shishido Family, where I experienced the washi papermaking process for the first time in my life; I was so excited.

Washi paper’s production process bears similarity to the ordinary paper, but it has to be made by hand in a traditional manner

Mr. Nobushige has to go through a long and intricate process. Winter is the optimal time to make washi, as pure, cold running water in Marumori inhibits bacteria, preventing the decomposition of the fibers.

Relies heavily on manual methods, the Shishido couple have to cooperate with each other in the washi-making process.

The washi paper of Marumori Washi Workshop is made using fibers from the bark of the gampi tree and the mitsumata shrub. Everyday Mr. Nobushige and Ms. Ritsuko get up early in the morning, and obtain the raw material for washi from the forest.

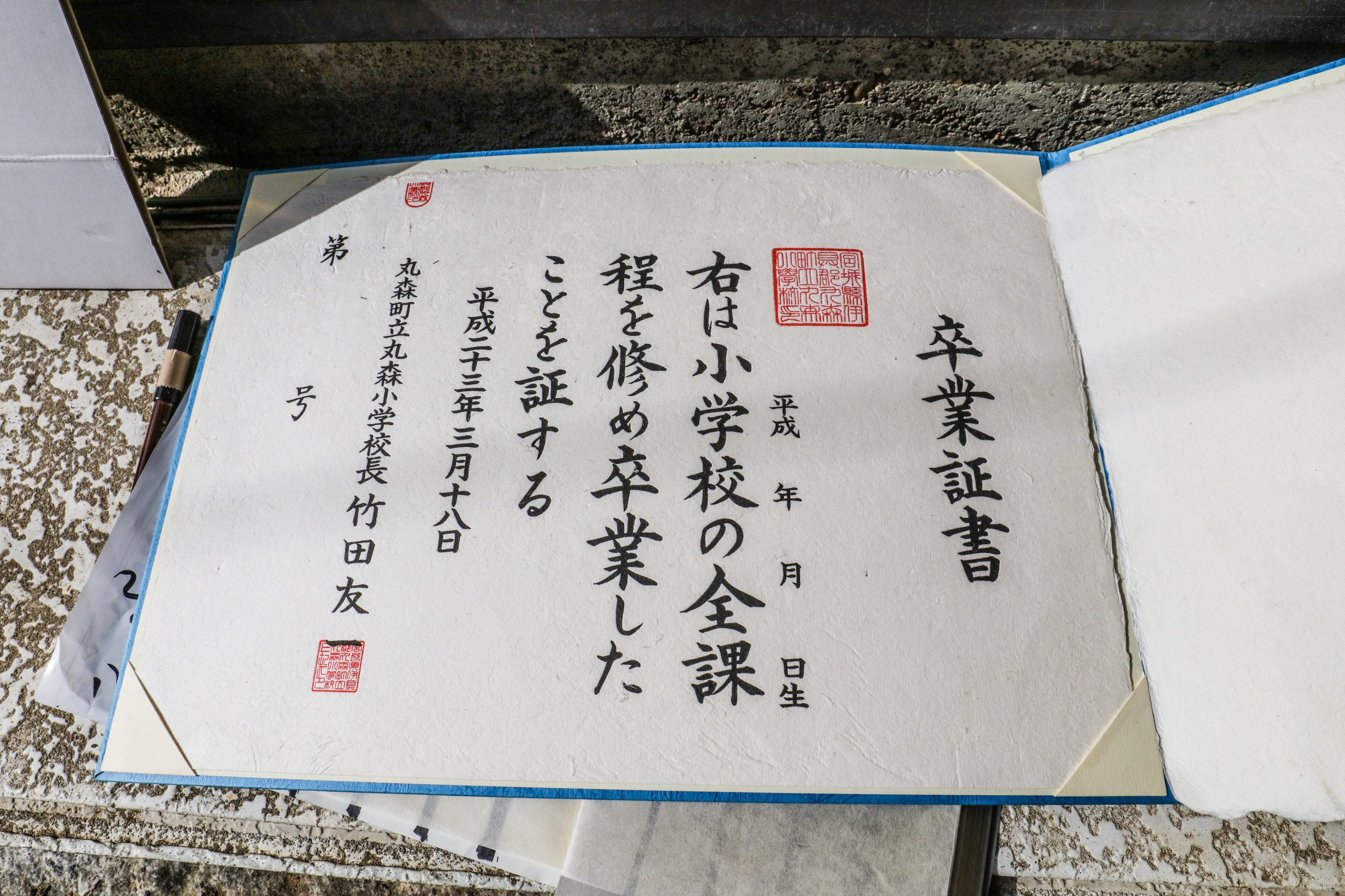

Washi is generally harder than ordinary paper made from the wood pulp, and is used in many special occasions. The certificate of graduation of the elementary schools uses the washi paper made in Marumori Washi Workshop.

The Marumori Washi Workshop also provides post-card making experience using washi.

The Address of 丸森手すき和纸工房 is as follows.

白木屋 – A Small but Cozy Noodle Restaurant

The White Wood House (白木屋) is a famous noodle restaurant in Marumori town and a good place for friends to get together.

The White Wood House is more than a hundred years old, and the owner of this restaurant is now the fifth generation. In fact, the fifth generation and her mother (the fourth generation) together run this restaurant now, and their biggest joy in life is making noodles.

The White Wood House’s noodle was not only delicious, but good-looking as well. I ordered the big size of Ramen this noon. Despite the fact that it’s very tasty, I could finish it.

The address of the 白木屋 is as follows.

藍染工房野風-Make The Textile That Literarily Can Eat

In the afternoon, I experienced textile dyeing for the first time in my life under the guidance of the sensei in Aizome Dyeing Workshop (藍染工房野風).

Textile dyeing is the process of adding color to textile products like fibers, yarns, and fabrics. There are two classes of dye, namely natural and man-made. The Aizome Dyeing Workshop provides the experience of natural dyeing process.

Natural dyeing process is not only time-consuming, but very costly as well. But its advantage is also very obvious – it’s clean, neat and much more user-friendly. The dyestuff was so natural and clean that you can taste it using your finger.

The Germans produced artificial dyes to achieve a broader range of colors and to render the dyes in a cheaper and faster manner, however, the Aizome Dyeing Workshop insisted its natural dyeing process, in order to produce natural products that distinguish themselves from the daily common textiles.

This is the pot for the dying process, usually it takes 8 to 12 rounds to finish dyeing.

After dyeing the cotton for several rounds, I cleaned the cotton using the cold water. The cotton was then dried and ironed.

I like what I made in the afternoon. Except tablecloths and handkerchiefs, the main production of Aizome Dyeing Workshop is actually high quality cotton cloths with special dyeing patterns. The navy blue is so mysterious that as if I am absorbing blue directly from the ocean. The Address of 藍染工房野風is as follows.

Japanese Preserved Radish-The “Caviar” among Vegetables

Radish is known as one of the healthiest vegetables in the world. But the Japanese preserved radish is even healthier. This afternoon I am lucky enough to experience the luxury Japanese preserved radish and it was really great.

The white carrot is cut into bulks and then get dried in the sun.

When the drying process is done, the producers will gather together and classify the preserved radishes according to its size. The smaller the radish is, the more expensive it could sell.

This is because the more condensed the preserved radish is, the more nutritive it becomes.

The Japanese preserved radish can only be made in the winter, for it has to go through a “zero point” process which locks the essence of the white carrot while losing its moist.

The preserved food of this area comes from ancient wisdom of surviving in the wild, provides people in Tohoku area with nutritive and delicious food in the winter.

The Japanese preserved radish is sold national-wide and has become one of the favorite winter food of Japanese people.

I tasted the cooked Japanese preserved radish this afternoon, it was very chewable and delicious.